Converting a shop into an energy-efficient repair facility involves a strategic audit of current energy use, identifying inefficiencies like outdated equipment and poor insulation. Upgrading to energy-efficient models, installing smart thermostats, and enhancing insulation reduces consumption and costs. Advanced technology, such as smart lighting and HVAC systems, optimizes operations, cuts waste, and promotes sustainability, leading to long-term savings.

Transforming your existing shops into energy-efficient repair facilities is a multi-step process that can significantly reduce operational costs and environmental impact. Start by assessing energy consumption through a comprehensive audit to identify areas for improvement. Implement efficiency measures like upgrading equipment and improving insulation. Optimize operations with smart lighting and HVAC systems. By following these steps, you’ll create a more sustainable and cost-effective repair facility.

- Assess Energy Consumption: Audit Existing Shops

- Implement Efficiency Measures: Equipment Upgrades & Insulation

- Optimize Operations: Smart Lighting & HVAC Systems

Assess Energy Consumption: Audit Existing Shops

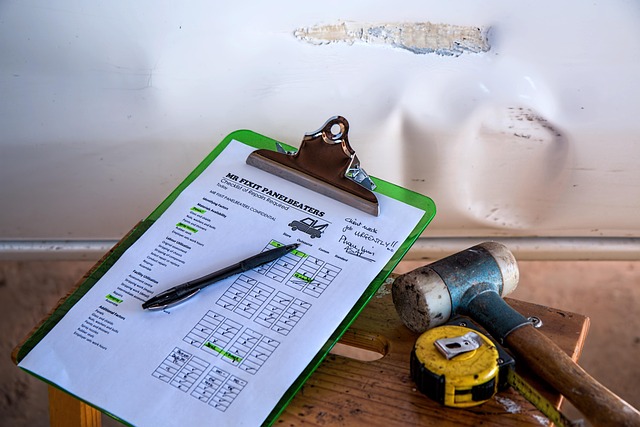

Converting existing shops into energy-efficient repair facilities starts with a thorough assessment of current energy consumption. Conducting a comprehensive audit on the automotive collision repair or car repair shop is essential to identify areas where energy can be conserved and costs reduced. This process involves evaluating every aspect of the shop’s operations, from heating and cooling systems to lighting and equipment usage. By analyzing data on energy usage patterns, you gain valuable insights into inefficiencies that might be costing your business money and contributing to environmental impact.

The audit should also consider specific tasks like auto glass replacement, which often involves energy-intensive processes. Understanding how these operations consume energy enables targeted interventions. For example, replacing outdated equipment with energy-efficient models, installing smart thermostats, or enhancing insulation can significantly reduce energy costs while transforming your shop into a more sustainable and eco-friendly energy-efficient repair facility.

Implement Efficiency Measures: Equipment Upgrades & Insulation

Converting existing shops into energy-efficient repair facilities involves a strategic approach to enhance operational sustainability and reduce environmental impact. One of the primary steps is to implement efficiency measures, starting with equipment upgrades. Outdated tools and machinery contribute significantly to energy consumption, making it imperative to replace them with modern, energy-efficient alternatives. For instance, switching from conventional paint booths to more efficient models can save a substantial amount of energy and reduce greenhouse gas emissions.

Insulation is another critical aspect that cannot be overlooked. Proper insulation in workshops and repair bays helps maintain ideal temperatures year-round, reducing the reliance on heating and cooling systems. By minimizing heat loss during colder months and keeping facilities cool during hot seasons, adequate insulation contributes to overall energy conservation. This not only translates to lower utility bills but also fosters a more comfortable working environment for staff, boosting productivity in collision repair centers or car body repair shops.

Optimize Operations: Smart Lighting & HVAC Systems

Converting an existing shop into an energy-efficient repair facility starts with optimizing operations through advanced technology. Smart lighting systems that automatically adjust based on natural light and occupancy can significantly reduce electricity consumption, especially in larger workshops where lights are often left on unnecessarily. Additionally, integrating smart HVAC (Heating, Ventilation, and Air Conditioning) systems allows for precise temperature control, ensuring energy isn’t wasted cooling unoccupied spaces—a major step towards making your car body restoration or Mercedes Benz repair center more eco-friendly.

For instance, implementing variable frequency drives in HVAC units can optimize airflow and temperature regulation, leading to substantial energy savings without compromising on comfort. These smart systems can learn patterns and adjust settings accordingly, much like a well-oiled machine. In the context of an auto collision center or any repair facility dealing with various vehicle makes and models, such efficient systems not only promote sustainability but also contribute to long-term cost savings while ensuring optimal working conditions for staff and vehicles alike.

Converting existing shops into energy-efficient repair facilities is a viable path toward sustainability and cost savings. By assessing energy consumption, implementing targeted efficiency measures like equipment upgrades and insulation, and optimizing operations through smart lighting and HVAC systems, businesses can significantly reduce their environmental impact while enhancing operational efficiency. Embracing these steps paves the way for a greener future, ensuring repair facilities play a vital role in a more sustainable world.